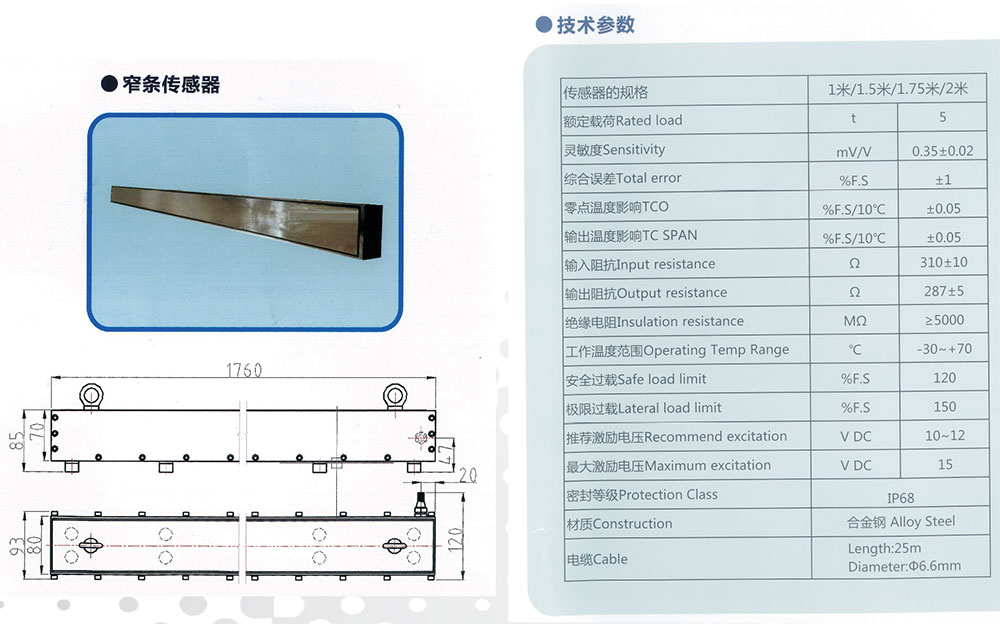

Narrow strip sensor

Mechanical combination structure, sensor individual and steel plate rely on physical structure, resistance strain principle, when the sensor is stressed to produce mechanical deformation, the size of the mechanical deformation to reflect the size of the force.

Classification:

Off-site non-stop detection system

Key words:

E-mail:

Product Introduction

1. Mechanical combined structure. The individual sensor and the steel plate are composed of physical structure. The principle of resistance strain type produces mechanical deformation when the sensor is stressed, and the size of the mechanical deformation variable reflects the size of the force.

2. Complete wheel load force measurement under static state. The vehicle in motion generates incomplete wheel load force, which is greatly affected by speed. The complete deformation of the main beam is detected and an analog signal is generated.

a. Static Level 3.

B, verification dynamic error: ≤ ± 0.5%, use error: ≤ ± 1%,

C, verification dynamic error: ≤ ± 0.5%,

D, use error: ≤ 1%,

E, the length of the carrier is 1040mm, the effective detection area is about 900mm, the contact area between the steel structure and the road surface is too large, it is easy to loosen, the steel plate is deformed, and it is easy to produce permanent deformation.

F, direct layout, according to the width of the road to customize the size of the flat plate, adjacent flat plate direct seamless docking, no border design, to achieve complete full paving, full-width road weighing without dead corners. Accurate weighing, the accuracy is greater than the dynamic level 5, the impact is small below 25 Km/h, and there is a linear law effect above 80 Km/h.

Weighing principle, characteristics and application

●Principle: When the wheel passes through the narrow strip sensor, the strain gauge attached to the elastic body feels the dynamic strain, and the Wheatstone bridge composed of it generates voltage signals proportional to the wheel load. These electrical signals are sampled by a special instrument at high speed, After processing and calculation, the axle weight and vehicle weight of the vehicle running on it can be obtained.

● Features: Integral elastomer structure, the elastomer is made of the whole material processing, with impact resistance, anti-partial load capacity, high accuracy level.

The horizontal output signal of the sensor is consistent. Through the special Wheatstone bridge design, the output signal of the sensor is consistent along the length direction, that is, no matter the wheel is pressed on any part of the sensor, the entire sensor has a consistent linear signal output.

Special seal protection design, the use of special seal protection treatment, isolation of the impact of the sensor stable rain, oil and other interference factors, to achieve long-term stability of the sensor.

Technical parameters

Product Performance

information platform system software

The life and safety of highways and bridges have caused frequent vicious traffic accidents. In recent years, the state has stepped up efforts to control overloading, but overloading has been repeatedly prohibited. The system mainly consists of three subsystems: high-speed non-stop detection system, precision inspection system, and source control system.

The information platform is a comprehensive software and hardware system integrating dynamic automatic weighing detection system, vehicle capture recognition system, illegal behavior notification system, video monitoring system, vehicle information collection and processing and case office automation system.

High-speed non-stop detection system

The system is mainly composed of high-definition bayonet video monitoring system, panoramic video monitoring system, high-speed dynamic weighing system, information release system and pre-inspection management platform. The high-speed dynamic weighing system can dynamically weigh high-speed vehicles. The total weight, axle weight, axle number, speed and other information of the vehicles can be detected in real time through the system. The bayonet system can identify the license plate number in real time, and superimpose the license plate number, vehicle weight, axle weight, over-limit rate, speed and other information on the bayonet to capture pictures to provide effective law enforcement basis for the later period, the panoramic video monitoring system can record the process of the vehicle passing through the weighing area in real time, and save the video recording to provide effective information for later review. If the dynamic weighing system detects the vehicle overrun, the vehicle license plate information and overrun information will be sent to the information release system to prompt the driver of the overrun vehicle to go to the front detection station for review, and at the same time, the overrun information will be sent to the background management center to prompt law enforcement personnel for law enforcement.

precision inspection system

The system is mainly composed of dynamic and static weighing body, high-speed railing machine, axle identifier, weighing sensor, license plate recognition camera, display screen, weighing industrial computer, back-end management software, etc. The system can automatically guide over-limit vehicles to enter the weighing area for detection. The system can automatically identify the license plate number and detect the total weight, axle number, axle weight, over-limit rate and other information of the vehicle, and upload it to the background management system to the weighing list automatically, if the vehicle exceeds the limit, the background can automatically generate law enforcement documents, saving law enforcement personnel time and improving work efficiency

Specific functions

1. Picture capture and video support character superposition. Information such as weighing data, vehicle type and overload can be superimposed on the captured picture as the basis for overload alarm and law enforcement.

2. Voice prompt of super detection data, automatic voice command vehicle up and down detection.

3, strict authority control, responsibility to the people, put an end to super-power operation, log records all operations.

4. Infrared vehicle positioning and anti-cheating function. The overweight vehicle is positioned through infrared shooting to prevent vehicle cheating from avoiding over-detection.

5. Support LED synchronous display. After the vehicle detection is completed, the vehicle number, gross weight, axle number, overload rate and other information will be displayed. The system has the characteristics of comprehensive, accurate and standardized detection data, fast data acquisition and processing and response, comprehensive and detailed inquiry and maintenance data, rigorous and convenient case processing process, automatic and rapid production of document materials, etc.

The system is developed based on a mature and stable Java platform, integrates advanced middleware technology, and adopts a cluster deployment architecture to ensure efficient and stable operation, and can smoothly expand and upgrade according to future business growth.

Previous Page

Tengyu weighing instrument, the choice of quality

Perfect service management guarantee mechanism

It covers pre-sales consultation, in-sales follow-up and after-sales support to ensure that customers can receive timely and professional services at all times.

Strong R & D capability

The company is equipped with a technical center and has a high-quality technical development team, of which 80% are bachelor's degree or college degree or above, and 35% are all kinds of professional and technical personnel.

Strong technical equipment strength

The introduction of international advanced level of key technology and equipment, with CNC machining center, CNC lathe, CNC laser cutting machine, CNC plasma/fire cutting machine, CNC bending machine, vacuum heat treatment furnace and a number of modern industrial technology and equipment; and equipped with shot blasting production line, large scale coating production line and other advanced equipment

Previous Page

Related Products

Immediate Consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!